The merger of Ritrama, Arconvert, Manter and Acucote led to the creation of a Fedrigoni division specifically for the design and production of self-adhesive materials.

More than just suppliers

We focus on what makes us different from everyone else, not on what makes us the same. And this is what we want to offer you, because we believe that there’s magic in how we combine design with technology.

This is why we want to be more than just suppliers. We want to be your partners who bring innovation to your self-adhesive projects.

Side by side with brand owners

We know that the market is very differentiated, and we can provide brand owners with top-class solutions for the most varied applications, thanks to our strong expertise in the industrial segment, as well as in different and complex industries.

Guidance, technical experience and capability on a global scale are the features that make us a reliable partner and highly capable problem solvers.

This is the house for designers

We are here to inspire, amaze and present to you the many different solutions we offer to all designers, to create something new and beautiful. We are here to make you shine and to be the perfect partner, offering the best products with the best delivery options, whenever you want and wherever you are.

Different needs for different printers

Traditional and large format printers, we’re talking to you.

Whether you print on our roll materials, offset sheets or graphics sheets, we’re here to satisfy your every need. We know how important it is to have what you want on time and at the right price, regardless of what size printer you are, the material you print on or the supplier.

Answer all your clients’ requests with us

Fedrigoni Self-Adhesives offers an extensive assortment of ranges and products so it’s hard not to find what your clients are asking for.

With us you can get everything you need from the same Group, meaning you will be able to fulfill standard as well as more specific requests.

The industries we serve

Find out who we serve and how, knowing you can count on our integration with the world of Fedrigoni.

Because if the future’s ahead of us, that’s where we’re heading.

Food

Beverage

Wine, Spirits & Craft Beers

Luxury

Beauty & Personal Care

Home Care

Pharmaceutical & Health Care

Transport & Logistics

Advertising & Promotion

Retail

General Signage

Corporate Branding

Architecture

Office

Tailor-made

Automotive

Durables

Oil, Lubricants, Industrial Chemicals

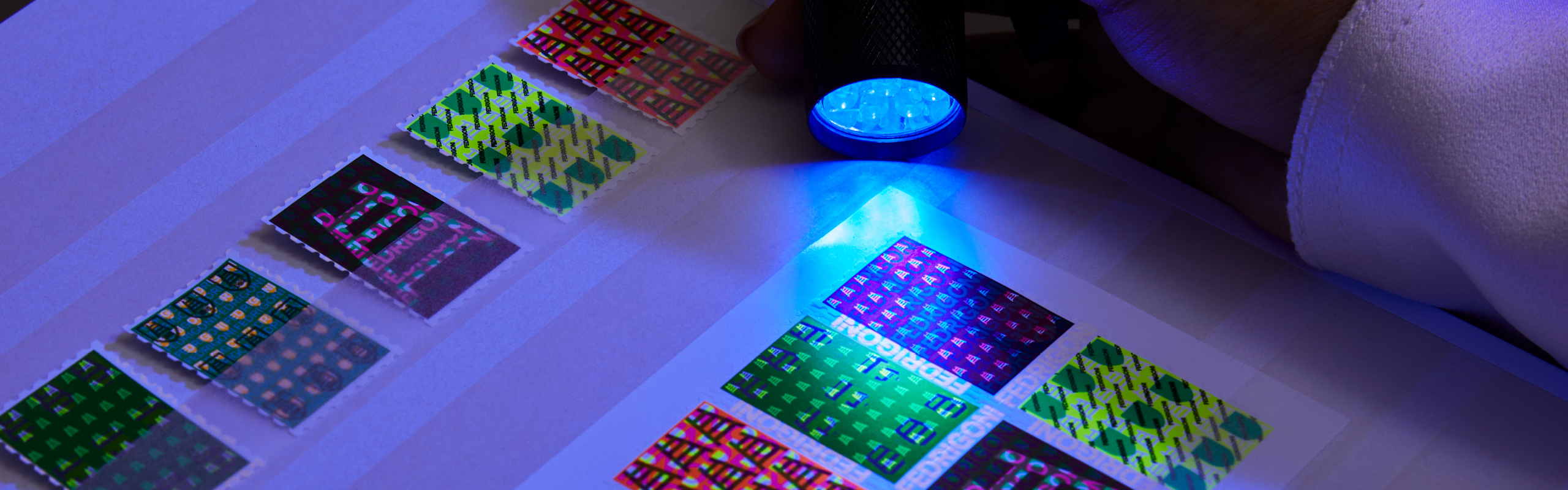

Brand Protection & Security

Governmental

News

Join us at Packaging Première Milan

Packaging Première Milan is the trade show that sets the stage for beauty, luxury, and cosmetic packaging, offering innovations to meet the challenges of this ever-changing world. Visit us at the Fedrigoni booth to…

Join the call for entries for the Fedrigoni Top…

Like the bountiful harvest in a well-tended kitchen garden, our event represents the culmination of hard work, dedication, and ingenuity across our entire value chain. With a prestigious jury comprised of esteemed professionals from various…

Introducing our range of compostable films

In alignment with our commitment to ensure that 100% of our standard product portfolio offers options for recyclability or reuse by 2030, we are proud to introduce our new range of compostable films. Tailored to…